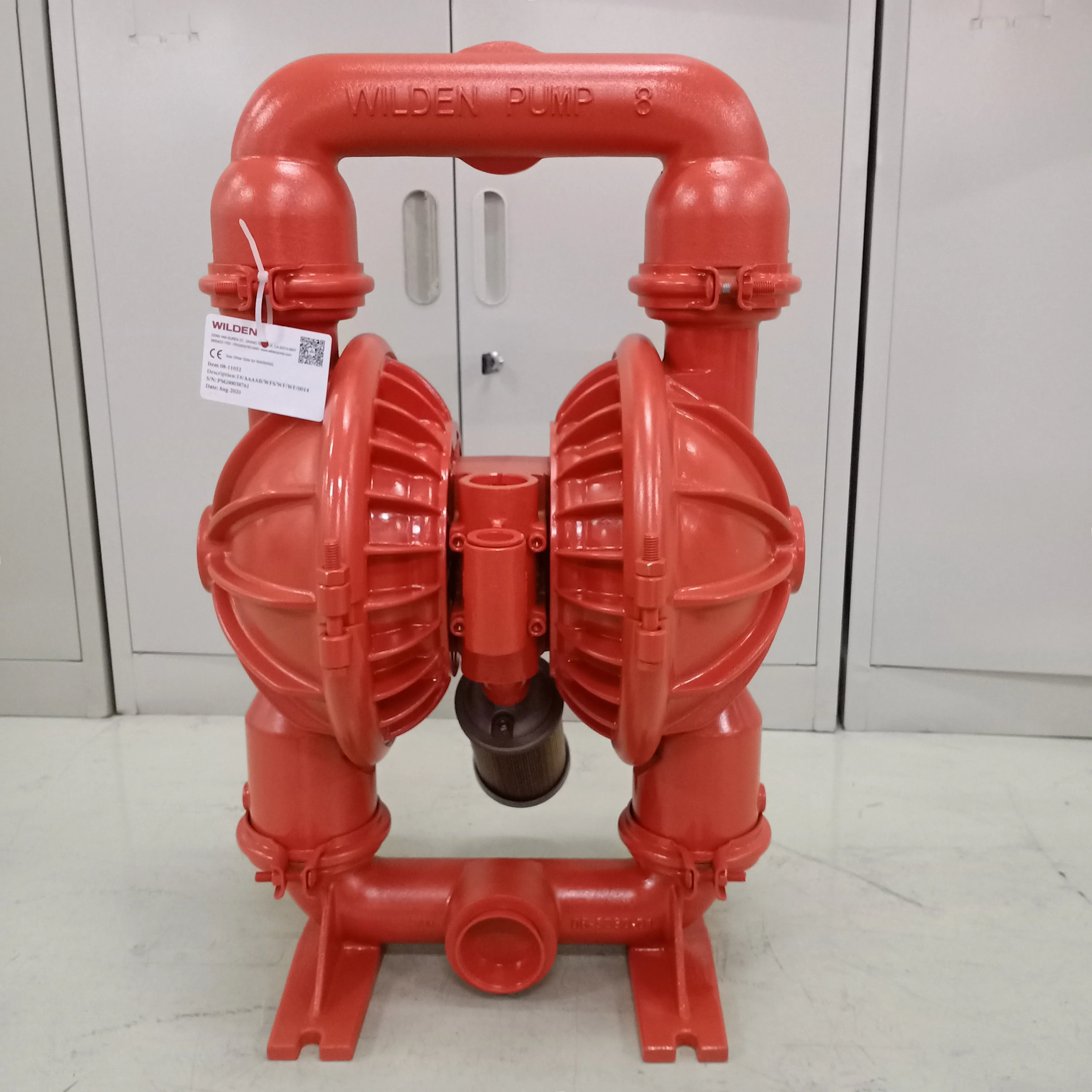

All The Important Parts of Pump

In this text, we will discuss the basic pump elements that are responsible for ensuring successful fluid flow through a reciprocating double diaphragm pump. These parts are engineered specifically for the purpose of working efficiently, which means that they remain uninterrupted during a pumping procedure.

Benefits of hydraulic pump parts

Essential pump parts are considered the back bone to the complete pumping system. Checking: All of these need to be checked for operating the pump smoothly and as well as safely. These parts, in combination with one another, better ensure the durability of the pump while also helping to maintain consistent fluid flow since they eliminate cavitation and wear - improving effectiveness as well reducing drop-off periods.

Revolutionary Essential Parts of Pumps

Essential pump parts are among the pumps that have been revolutionized by technological advancements and materials developments over time. These have become more robust and porous, precisely through better materials quality but also changed designs. This improvement results in lower downtime of the pump and reduced maintenance frequency.

Safety Is Important

Above all, safety is a major factor in the operation of pumping systems and their components. Hazards like lubrication oil fires, mechanical failures and hazardous fluid leaks have the potential to cause numerous safety risks. Pump parts that must endure high pressures and temperatures need to be made of strong, dependable materials which ensure workplace security.

Essential Pumping Accessories And How They Work

It is an easy process to use the essential pump parts. Correct assembly of these components is critical for the pump to function efficiently. This requires regular monitoring to avoid premature wear in the parts and to replace damaged components before they completely give out. By substituting poor quality parts, you could cause the system to fail which can translate into operational downtimes and in worse cases potential harm or damage of a facility.

Service and Quality

When you purchase typical pump accessories, service and quality will always be in concern. Customer service in terms of proper after-sales support, quality control checkups to ensure the diaphragm pump spare parts highest standard, and timely delivery is an integral part. Choosing well-known suppliers that provide only the highest quality products and best customer service, makes is such a delightful experience.

Uses Of Vital Pump Parts

These materials allow essential pump parts to be implemented across a large selection of sectors including industrial, food and beverage, as well as agricultural applications. In order to prevent this, it is important aodd pump parts that the right parts are used - and for them we have to know exactly what different systems need.

Conclusion

In the line of any pumping system are basic pump parts which would be so important. Their combined efforts make for a smoother and more streamlined pumping process, increasing the overall safety. These parts have evolved to be more reliable, durable and easier to use as they were continuously improved upon by a variety of material developments. Proper use, replacements as needed and choosing the right best products from reliable manufacturers are key to ensuring that you enjoy top efficiency in operating your most important pump.