A diaphragm pumpOspecially engineered piece of equipment which responsible for widely service in various industries that allowed it to transfer liquids and gases seamlessly. They have become more popular because of all the benefits they provide such as innovation, security, simplicity and qualitylisteners. In this post, we will discuss the versatility of diaphragm pumps so you can understand how different businesses use them.

Advantages of Diaphragm Pumps

Versatility: Diaphragm pumps are highly versatile. From food and beverage processing to chemical, pharmaceutical manufacturing industries these pumps find applications. They can not only used for a diverse range of applications but also provide fast efficient services required to move both liquids and gases swiftly yet accurately. Their self-priming function also allows them to automatically prime the pump without any assistance.

Innovation in Diaphragm Pumps

Over the years, diaphragm pumps have seen many improvements to become more versatile and reliable as well as efficient. One great illustration of those improvements is the use of new materials for constructing pumps. Pumps now benefit from being made with materials such as stainless steel and Teflon, meaning that they are far less susceptible to corrosion damage -this gives them an extended lifespan compared to previous pump designs making the use of these pumps in tough environmental conditions substantially safer.

Advantages and Disadvantages of Diaphragm Pumps

One of the safety features diaphragm pumps are noted for is. Their user-friendly industrial security features such as pressure relief valves and leak detection systems reduce workplace hazards. In addition to this, their low maintenance and servicing attribute it worth keeping up which further means lesser accidents or injuries taking place.

Diaphragm Pumps are Used

Diaphragm pumps are an important asset in the transportation of fluids (and sometimes gases) throughout various industries involving chemical processing, food and beverage, pharmaceuticals; even mining or waste management. Also, they are essential in agriculture (seed coatings), Oil and Gas or water treatment industries. Because of their overall handling viscous liquids and solids; positive displacement pumps, they are able to transport fluids from azeotropic solutions easily.

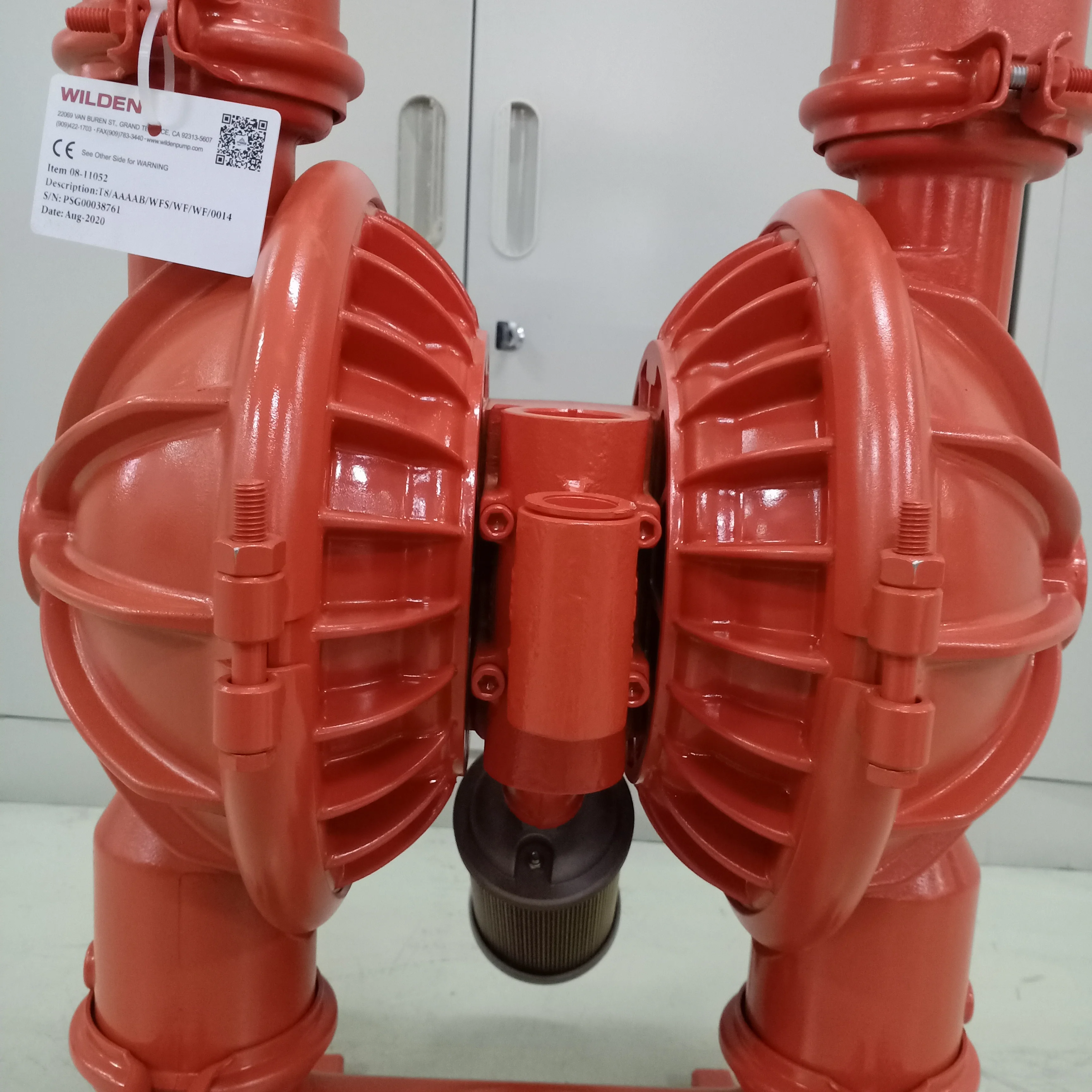

How Diaphragm Pumps Work

In other words, diaphragm pumps work like this: It uses a diaphragm that moves in balance within one end of the chamber. The diaphragm moves outward and this will create a partial vacuum that causes the gas or liquid to rush into in another chamber. On the contrary after this, when the diaphragm is pulled inwards it pumps out liquid or gas respectively through outlet valve. The pump is very easy to use, just connect the inlet hose with liquid or gas source and connect outlet hose with receiver container or pipeline.

Diaphragm Pumps Maintenance Practices

Diaphragm pumps need maintenance from time to time to maintain efficiency and safety of the entire operation. This includes washing the pump and looking for any signs of damage or wear. Additionally, to keep the pump running in good nick it's important to replace things like diaphragms, valves and o-rings which get worn or damaged. Proper maintenance can help in increasing the life of pump and reducing breakdown or accidents.

Importance of Pump Quality

Choosing a High-Quality Diaphragm Pump In sum, premium pumps are made with quality materials for longevity and safety purposes, intuitive user interaction to minimize training time required by professionals during an emergency situation. Their effectiveness offers quick, positive transferability of diaphragm pumps liquids and gases. When you purchase a reliable diaphragm pump for sale, this ensures your pumping demands are addressed both safely and efficiently.

Different Uses of Diaphragm Pumps

This makes diaphragm pumps Ideal for a wide range of industries as they can be used on such vast applications versatility, safety and ease of use, make them the automatic choice when specifying process equipment. They are used in chemical processing, food and beverage industry pharma manufacturing (Licensed from Rawpixel.com/shutterstock), mining, waste diaphragm pump for sale treatment management agriculture oil & gas (Provided by Pexels/RF._.studio) as well water treatment industries. They are capable of handling liquids, gases and high-viscosity fluids, solids and slurries as well which makes them versatile for various applications.

We hope you agree, diaphragm pumps are universal and with such a high-capacity of performance makes them applicable in many different industries. Their safety, simplicity, high performance and air operated diaphragm pump versatility make them the perfect option for all kinds of pumping needs. Their creative designs can be tailored and amended to meet various needs, something that sets them apart from other tools in any business activity.